How is Tarnish Removed from Electronic Contacts?

Tarnish is a chemical reaction between electrical contacts and the air. To get rid of the tarnish, the tarnish has to be rubbed off. Unplugging the device or using a pencil eraser is a safe way to rub the tarnish off the contact.

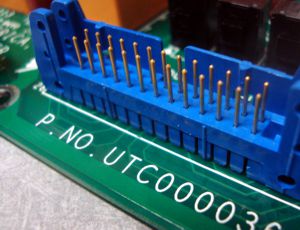

No matter what material the pins on this ribbon connector are made of, tarnish can eventually build up, interfering with the free flow of electricity. The only way of removing the tarnish is to rub the spring contacts in the plug against the pins. Of course, where the metal-to-metal contact is made, the tarnish on the spring contacts also get rubbed off at the same time.

By Douglas Krantz

Has this ever this happen to you?

The electronic circuit you're servicing isn't working. You take it apart, look at it, and don't see anything wrong with it. After reassembling, it works.

You know you didn't do anything to fix it, why does it work now when it didn't work before?

Tarnish on the Electrical Contacts

When this happens, it's usually a problem with tarnish on the contacts. Keep in mind, tarnish, like rust on iron, is a chemical reaction between the metal surface of the contact and oxygen or other chemicals in the air.

Any electrical contact meant to separate and join again gets exposed, loses its luster with tarnish, and eventually starts impeding its electrical flow.

Electrical Contacts are Everywhere

Contacts are:

- Plugs mounted on the printed circuit board

- Wires connected to components

- Wires in crimp connectors

- Wires connected to front panel switches or controls

- Switch contacts

- Potentiometer wipers

- Screw terminals

Methods Used to Make Electrical Contact

There are two means of connecting electrical conductors to each other:

- Permanent Gas Tight Connection

- Temporary Exposed Connection

Permanent Gas Tight Connections -- Air Can't Penetrate -- on a molecular scale, air is kept out

- Solder -- (yes, solder is a conductor of electricity, but one of its many purposes is to keep the air out)

- Press-fit connections (insulation displacement) -- so tight that the air cannot creep between the wire and the contact (telephone 66 or 110 blocks are somewhat like that)

- Added substance like Vaseline or some other greasy material -- the grease doesn't conduct, but it prevents the entering of air or other chemicals

Temporary Connections -- Air can insert itself between the conductors -- the looser the connection, the easier it is for air to corrode or tarnish the contacts

- Spring contacts

- Spade Contacts

- Crimp Connectors

- Screw Contacts

- Circuit Board Edge Contacts

- Wire Nut Contacts

- Relay Contacts

- Switch Contacts

- Potentiometer Wiper Contacts

- Motor Brushes

Anything meant to be taken apart and put together again is not air-gastight and is exposed.

Non-Linear Resistance of Tarnish on the Contact

All connections have resistance. Direct metal-to-metal contact has a very low, linear, resistance: as the voltage goes up or down, the number of ohms does not change.

Tarnish between the conductors changes that - the resistance of tarnish is non-linear;

non-linear resistance is fickle. At 110 volts, unless the tarnish is really bad, the ohms are very low, possibly in the single digits. However the as the voltage is reduced to, say, 5 volts, the ohmage increases. In some cases, the resistance could increase to hundreds of ohms, or greater.

This is non-linear resistance and tarnish is a non-linear resistor.

High voltage signals get through the connection just fine, but low voltage signals might not get through, and then the equipment doesn't work.

Contact Cleaner as a Lubricant

If it's a dirt build-up on the contacts, contact cleaner does help. It carries away the dirt and grease.

The cleaner's greatest help, though, is as a lubricant. Preventing air from chemically reacting with the contact, the lubricant provides a thin coating of oil to the surface.

Once the oil evaporates, however, the anti-tarnishing benefits are gone.

Scraping the Surface - Cleaning Off the Tarnish

Instead of trying chemicals, to remove the tarnish or corrosion from the contact surface, what really works is scraping the tarnish off the metal.

Exercising the contacts (repeated metal-to-metal rubbing together of the contacts) -- as when the connections are taken apart and put together again quite a few times -- scrapes off the tarnish. Once the tarnish is scraped off, the connection is good until the tarnish can build up again.

Tarnish or corrosion becomes part of the surface of the metal, and for the contacts to conduct properly again, the tarnish has to be removed. Contact cleaner removes dirt or coatings from the conductors, but it isn't designed to undo the tarnishing chemical reactions; it won't dissolve tarnish.

CAUTION:

Be careful when scraping the metal surface to remove tarnish.

A file or other hard device will change the shape of the contact, and will probably ruin it. If you're deliberately scraping the tarnish off the contact, there has to be a balance between removing the tarnish and damage to the contact.

In other words,

don't overdo it.

Rubbing Off the Tarnish

Spring Contact

Whether they're edge board connectors or multi-pin connectors, most connections to printed circuit boards are spring connectors.

There is a metal-to-metal sliding as the plugs are mated, so unplugging and plugging the connector automatically rubs off the tarnish. If the springs can be tightened, the tarnish will take longer to build up again.

Edge board connectors on Printed Circuit Boards can also be cleaned off using pencil erasers, without too much damage to the connectors.

Screw Terminal

The screw contact itself may corrode or tarnish, but more likely the copper wire will tarnish.

Loose screws allow air between the wire and the screw terminal. Tightening the screw will do a little squishing of the wire, and this breaks up the surface tarnish, allowing the copper to make better metal-to-metal contact. Tightening the screw also reduces the amount of air getting between the screw terminal and the copper of the wire.

Switches and Relays

The higher end switch and relay contacts are meant to have metal-to-metal sliding as the contacts come together.

Usually this is enough to scrape off the tarnish, but if the switch or relay doesn't get used very often, or if the contacts are actually pitted or burned, the switch or relay may have to be replaced because the tarnish is too thick or pitting too severe.

Printed Circuit Board Flaws

Of course, a printed circuit board could be damaged. It could have a crack in one of the traces, or a poor solder connection. For the sake of troubleshooting, this type of flaw should be considered to be an electrical contact.

The trouble is, while trying to troubleshoot, flexing the board may rub the tarnish off the contact. This will, for an unspecified time, allow the board will work again. The unspecified time can be from a few hours (until your taillights disappear) to maybe months or years.

Contacts are Fragile

While troubleshooting and things suddenly start working, keep in mind that tarnish may have been rubbed off on the contacts.

Taking extra measures to find and remove the tarnish at this time may prevent the need to return again and again to troubleshoot.

But be careful.

Common sense is also needed - don't use an abrasive material like a "pen" eraser or Scotch Bright. Even a dryed out pencil eraser might be too harsh.

And remember the old addage, "

If it aint broke; don't fix it." If the device is working, making the contacts shiny won't make the device work better, making the contacts shiny only wears off more of the surface-contact material. Don't overdo any contact cleaning.